HIGHWAYS RESEARCH STATION

Highways Research Station was established in the year 1948. Foundation stone was laid by the former Governor of Madras, Thiru. Shri. Sri Prakasa in the year 1956 and the building was inaugurated by Former Chief Minister Thiru. K. Kamaraj of Tamil Nadu in the year 1957. Research on techniques, testing of materials adopted in Highways Construction and quality control for Road & Bridge works being executed in Highways Department are the primary functions of HRS. It also provides technical guidance to the personnel of Highways Department, whenever required. Highways Research Station is headed by the Director (Chief Engineer level officer) and functioning with 2 Joint Directors, 1 Superintending Engineer, 6 Deputy Directors and 17 Divisional Engineers.

THE OBJECTIVES OF HRS

The primary objectives of the Highways Research Station are,

- Research, testing & Quality Control

- Training.

- Road Safety

FUNCTIONS OF HRS:

- Researches on innovative construction materials and technologies.

- Testing on materials used for road and bridge works.

- Offering technical solutions for field issues.

- Ensuring quality of works in several stages.

- Capacity building of the Highways staff through training.

- Offering suggestion to Execution wings in Road safety measures for ensuring safe and seamless traffic.

- Offers technical guidance for geometric and junction improvements.

I. ACTIVITIES OF HRS:

1. ROUTINE ACTIVITIES:

HRS has four laboratories at Chennai viz., Soils, Concrete, Bitumen and Traffic Labs with state- of- the- art equipments. Well equipped eight regional laboratories are also functioning at Villupuram, Trichy, Thanjavur, Madurai, Tirunelveli, Salem, Tiruppur and Coimbatore.

Routine activities like testing of soil & rock samples, pile load tests for bridges, non-destructive tests on concrete members, material testing viz cement, steel, designing of flexible and rigid pavements, concrete and bituminous mix designs, evaluation of surface characteristics by road surface roughness tests, structural evaluation by carrying out Benklemen Beam Deflection Test (BBD) and Junction improvement techniques based on traffic and assessing the Vehicle Damage Factor (VDF) by axle load survey are being undertaken in the above laboratories.

II. LAB ACTIVITIES:

2.1. Crushed Stone Sand (M-Sand):

Crushed Stone Sand (M-Sand) is being used in Tamil Nadu Highways Department since 2015 as an alternate to River Sand. The manufacturing unit is being inspected by the Superintending Engineer (H), Construction & Maintenance and Divisional Engineer (H), Quality Control of the respective circles to ensure the quality of Crushed Stone Sand (M-Sand) and being used for various Highways Works.

A detailed study on the Crushed Stone Sand (M-Sand) obtained through Vertical Shaft Impact (VSI) Crusher unit with variation in percentage of micro fines (75 micron passing) was undertaken by HRS. It was observed that 28 days compressive strength achieved by using Crushed Stone Sand (M-Sand) are well above the compressive strength that achieved using River Sand and more than 1500 concrete mix design were evolved and used various construction works in Highways.

RCC Beam Test using Crushed Stone Sand |

RCC Slab Test using Crushed Stone Sand |

2.2.Remedial Measures for Rehabilitation of Distressed Bridges:

During the Year 2018 the following Old bridges requiring repair and rehabilitation were inspected by a team of HRS

- ROB at Km.123/2 of Old NH-45 Passing through Tindivanam town of Villupuram (H) C&M Division.

- Bridge at Km.0/2 of Pennaiyar bridge approach road (SHU-47) Kallakurichi (H) C&M Division.

- Thanthai Periyar Bridge across Cauvery River at km 0/385 - 1/850 of Musiri –Kulithalai –Pudukottai –Alangudi –Peravoorani –Sethubavachatram Road (SHU-71) in the jurisdiction of Karur (H), C&M Division.

During the year 2019, the following old Bridges requiring repair and rehabilitation were inspected by a team of HRS

- The Mayor Muthu Bridge at km 443/8-442/2 of Varanasi-Kanyakumari road (Abandoned NH-71) (SHU-73) in the jurisdiction of Madurai(H), C&M Division.

During the year 2022, the following old Bridge need repair and rehabilitation was inspected by a team of HRS

- Bridge inspection at Malliakkarai – Rasipuram – Thiruchengodu – Erode Road at Km 94/200 – 94/660 of SH – 79 (Pallipalayam Cauvery Bridge)..

|

Suitable remedial measures such as Sealing of Cracks, Guniting / Shotcreting, replacing the bearings, replacing expansion joints, repairs to wearing coat, Bed protection and river training works were suggested to enhance the service life and utilization of the bridges.

2.3 Roughness Test conducted

Roughness test was conducted for the roads in Output Performance based Road Contract for the Maintenance of TNRSP roads in presence of HRS Engineers. Further, the roughness test was conducted for Nagapattinam – Thoothukudi Road from Km 10/2 to 102/0 for both directions.

|

|

Roughness test for Nagapattinam – Thoothukudi Road from Km 10/2 to 102/0 |

On request, Roughness test was conducted for a length of 60.15 Km at the Chennai Outer Ring Road which is maintained by TNRDC Wing.

|  |

Riding Quality test conducted for assessing the Surface Roughness |

|

3.CONSULTANCY WORKS:

Apart from the routine activities, the following consultancy works have been carried out,

- Airport Authority of India (AAI) – Methodology to be adopted for improving CBR value of existing value in Runway Basic Strips.

- SIPCOT Industrial Park, Thervoykandigai – Design of overlay thickness using Benkleman Beam Deflection (BBD)..

- RITES – Design of GSB, WMM in existing holding yard for M/s Kamaraj Port Ltd.

- Satish Dhawan Space Centre, ISRO – Recommendations for the “Sriharikota – Sullurpeta road” to control carriageway submergence and erosion of road shoulders.

RESEARCH ACTIVITIES:

4.1. Completed Research Schemes:

The completed research schemes under Tamil Nadu Innovation Initiatives Fund (TANII) and their outcome are as follows,

4.1.1. Study on the effect of Nano clay in bituminous mixes

As Modified bituminous mixtures over the conventional hot bituminous mixes, the addition of nano clays viz., Bentonite Nano clay & Montmorillonite Nano clay as modifiers to the conventional bitumen enhance the mechanical properties & improves the performance against rutting and fatigue of bituminous mixes.

4.1.2 Study on performance of jute fibre reinforced cold bituminous mixes

Flexible road pavement are constructed using Hot Bituminous Mix which is manufactured and laid at high temperatures (140 to 175oC) requiring considerable fuel for heating which also causes environmental pollution. As an initiative for greener roads, increased attention is bestowed to the improvement and utilization of Cold Bituminous Mix, since Bitumen Emulsions are used instead of Bitumen. IRC:SP:100-2014 “Use of cold mix technology in construction and maintenance of roads using bitumen emulsion” specifies lower Marshall stability values for design mix of wearing course. Hence, modification is necessary for higher stability value comparable to hot mix design to suit high traffic conditions. Naturally available Jute fibre has been chosen for this study for adding with Cold bituminous mix and studying its performances.

The research method includes the Material selection, Material Characterization, Preparation of cold bituminous mix with various percentage of jute fibre dosage, with various lengths. Preparation of bituminous specimens (Marshall Method) with various percentage of binder, Conducting Marshall test on control mix and modified mixes in order to determine optimum binder content, accordingly performance tests were conducted and following inferences are obtained.

|

- c

- Jute fibre reinforced cold bituminous mix has better Rut resistance and Stability value.

- These mixes may be used in wearing course in Highways roads.

- It is environmental friendly with absolutely zero pollution. This mix helps in reducing green house gas emission.

- It is labour friendly that is no occupational hazard to the workers.

- Cold Bituminous Concrete mixes can also be laid in wet and humid climatic conditions..

4.1.3 Study on performance of bituminous pavement laid over stabilized subbase

This study aims to find out most economical pavement design technique by stabilizing granular layer, recycled asphalt and Geogrid interlayer with respect to conventional method of pavement construction.

From observation of seven stretches and data analysis & interpretation, Granular base and subbase with Geogrid performed well with minimum observed vertical compressive strain.

4.1.4 Study on Improving the CBR value of Subgrade soil by adding Quarry Dust

This study aims to improve the CBR value of the sub grade soil having CBR value less than 5.Adding 50% Quarry dust to soil having less CBR improve the CBR value from 2, 3 & 4 to 11, 12 & 14 respectively. Thereby reduces the construction cost by 34 %, 26 % & 22 % respectively.

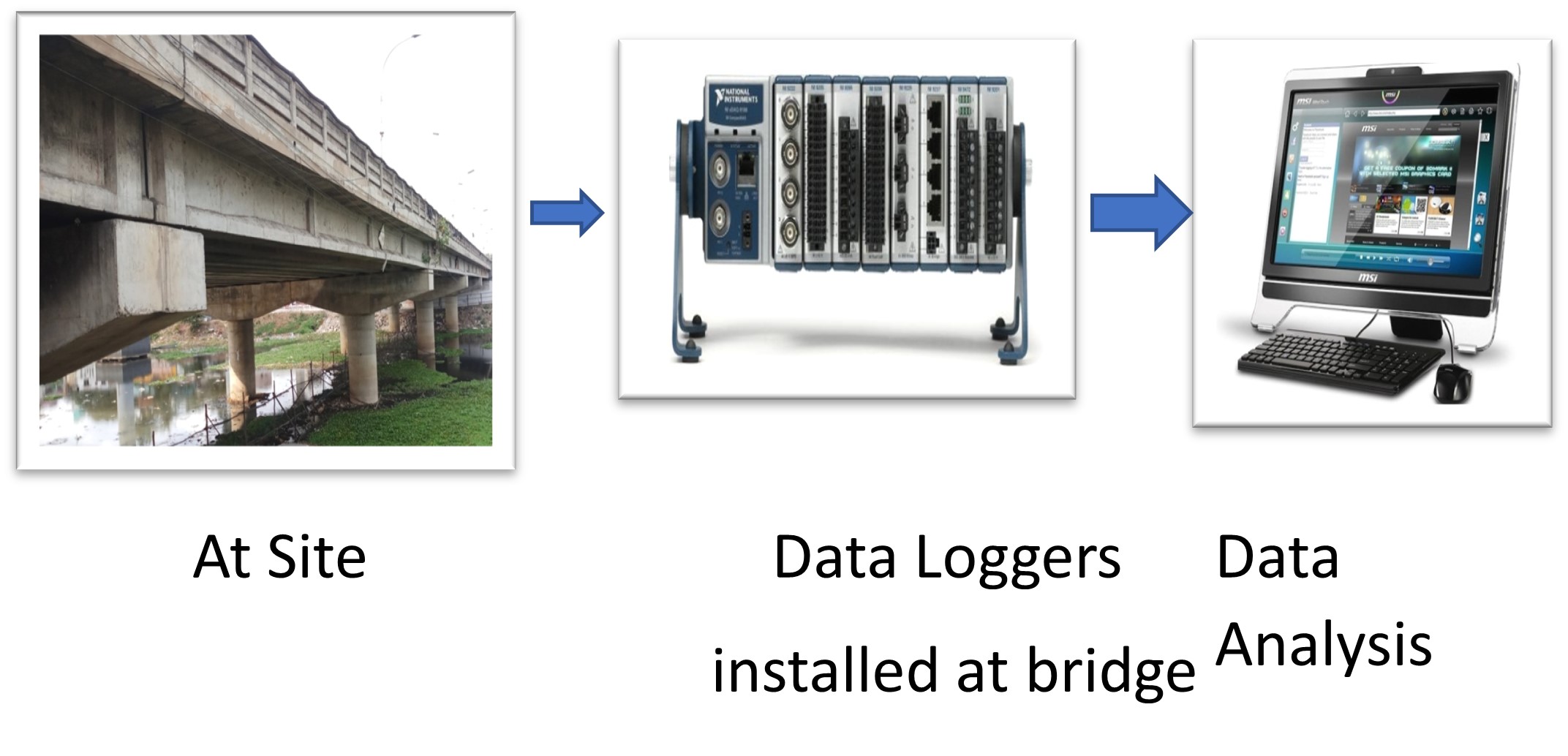

4.1.5 Bridge Instrumentation for Structural Health Monitoring System in Highways Department

- To enhance the performance of an existing bridge, instrumentation based diagnosis was studied by installing the sensors with data acquisition system and its accessories at the existing bridge (km 2/4 of Inner ring road Ekkattuthangal across Adyar river).

- This will also be helpful in studying the structural deformation on day to day basis.

|

4.1.6 To study the effectiveness of curing compounds on concrete pavement

- Based on the study, it was found that resin based curing compounds more effective compared to water based curing compounds.

- Curing compounds can be used at places where water curing is inconvenient or potable water for curing is not available.

- Also it reduces the huge quantity of potable water and labour for curing.

|

|

4.1.7 Accident study for Vulnerable Road User

This study is proposed mainly to suggest suitable remedial measures to reduce the road traffic accidents caused to Vulnerable Road Users (VRUs) in Urban corridors.

The study locations have been identified considering the occurrence of conflicts between vulnerable road users and vehicular movement, severity of conflicts, movement of pedestrians and dense traffic

For this study, 18 locations have been identified in three major cities viz.,Chennai, Madurai and Coimbatore. The performance analysis for the each location was carried out considering the parameters such as Footpath, pedestrian crossing, vehicular speed, etc., and suitable remedial measures to enhance the safety of vulnerable road users have been suggested.

|

|

4.2. Ongoing Research

4.2.1 Study on the technology of long lasting pavement with the construction of Circular Test for model study

Study on the technology of long lasting pavement with the construction of Circular Test for model study is to facilitate the accelerated circular test track for design of the long lasting flexible pavement in which no structural deterioration occur due to fatigue cracking and rutting. Loading is effected such that the limiting strains for Horizontal Tensile strain is 80µstrain and Vertical compressive strain is 200µ strain. The model pavement system would be tested for real time loading till the end of the design life, by accelerating the loading and environmental conditions and to suggest its suitability such that the wearing course alone needs to be changed thereby attaining the reduction in the periodical maintenance cost on the pavement.

|

|

|

5. IRC PAPER PRESENTATION

During the 81th annual session of Indian Road Congress held from 8th to 11th October 2022 at Lucknow (Uttar Pradesh), three technical papers were presented by the Engineers of Highways Research Station, Chennai, on behalf of Highways Department as detailed below:

5.1 Presentation on “Study on Performance of Jute Fibre Reinforced Cold Bituminous Mixes” by Er. C. Ayyadurai, Assistant Director (H), Bitumen Lab.,

|

5.2 Presentation on “To Study the Effectiveness of Curing Compounds on Concrete Pavement” by Sh. M. Anandaraj, Assistant Engineer (H), Concrete Lab .,

|

5.3 Performance of Bituminous Pavement Laid Over Different Combinations of Stabilized Base and Sub Base” by Ms. S. Kathya, Assistant Engineer (H), Soils Lab.

|

MEMBERSHIPS

The Director, HRS is a member of the following committees of Indian Road Congress (IRC),

- Accreditation of New Material and Techniques Committee

- Human Recourse Development Committee

- PCD 06 – Bitumen, Tar and related products sectional committee

The Joint Director, HRS is a Principal member of the following committee of BIS,

REVENUE EARNED

During the financial year 2022-23, all the laboratories of Highways Research Station have conducted 23631 tests and earned revenue of Rs.24.65 crore.

QUALITY CONTROL

Nine Quality Control Divisions are functioning to ensure the quality of works in construction of roads and bridges being executed by Construction & Maintenance wing, NABARD & Rural Roads wing and Metro wing. .

II. TRAINING CENTRE

An exclusive Training Centre is functioning to train the Engineers and Non technical officials of the department, to enhance their knowledge and improve their performance. Training Centre has the following facilities:

- 250 capacity State-of-the-art Auditorium

- Four Numbers of Class rooms, each of 40 seating capacity

- Mini conference hall with 25 seating capacity

- Computer Laboratory with 25 work stations

- Library

- Hostel with 32 double-bedded rooms & 8 triple-bedded rooms

- Gymnasium, Indoor & Outdoor games

COMPREHENSIVE TRAINING PROGRAMME

A Comprehensive Training Program (CTP) has been designed to cover all the Engineers and Staff of the department over a span of 5 years. Guidelines for successful implementation of CTP have been issued vide G.O. (4D) No.1 of H&MP (HR1) Dept., dated 18.03.2022.

The Comprehensive Training Program was inaugurated by the Hon’ble Minister of Highways & Minor Ports Department on 25.04.2022.

TRAININGS CONDUCTED UNDER CTP

|

S. No |

Training Programme |

Start date |

End date |

No of participants |

|

|

1 |

Design, Construction, Maintenance & Quality Control of Flexible Pavement |

TFT -01 |

25.04. 2022 |

30.04.2022 |

39 |

|

2 |

23.05. 2022 |

28.05.2022 |

38 |

||

|

3 |

12.09. 2022 |

17.09.2022 |

40 |

||

|

4 |

Communication Skills for Non-Technical |

NPQ -01 |

18.05.2022 |

20.05.2022 |

27 |

|

5 |

Construction, Maintenance & Quality Control of Bridges & Grade Separators |

TFT - 02 |

09.05. 2022 |

14.05.2022 |

34 |

|

6 |

06.06. 2022 |

11.06.2022 |

36 |

||

|

7 |

20.02.2023 |

25.02.2023 |

36 |

||

|

8 |

Communication skills for Technical |

TPQ -01 |

18.10. 2022 |

20.10.2022 |

41 |

|

9 |

Road Safety – Relevant Highway Engineering Aspects |

TFT -03 |

09.05. 2022 |

13.05.2022 |

38 |

|

10 |

30.05. 2022 |

03.06.2022 |

35 |

||

|

11 |

20.06. 2022 |

24.06.2022 |

37 |

||

|

12 |

22.08. 2022 |

26.08.2022 |

43 |

||

|

13 |

26.09. 2022 |

30.09.2022 |

45 |

||

|

14 |

30.01.2023 |

03.02.2023 |

36 |

||

|

15 |

20.02.2023 |

24.02.2023 |

39 |

||

|

16 |

Contract Management & Conflict resolution |

TFT -04 |

19.12.2022 |

23.12.2022 |

40 |

|

17 |

Induction cum Foundation Training Programme for JDOs |

Batch I |

06.02.2023 |

10.02.2023 |

39 |

|

18 |

Batch II |

06.02.2023 |

10.02.2023 |

39 |

|

|

19 |

Batch III |

27.02.2023 |

03.03.2023 |

39 |

|

|

20 |

Batch IV |

27.02.2023 |

03.03.2023 |

33 |

|

|

Total |

754 |

||||

During 2022-23, 577 Engineers and 27 Non – Technical officers have been trained so far on various topics. Also 150 Junior Drafting Officers appointed in August 2022 have been given Induction cum Foundation Training. During all training programs, Yoga and Meditation classes are conducted in the early morning by eminent yoga teachers.

Apart from CTP, training programmes have been conducted to 26 numbers of Deputy Collectors and 110 Section Officers of Secretariat.

Students from various Engineering colleges and polytechnic colleges have attended in-plant training at laboratories of HRS and have been guided on their project works.

For the entire Highways Department, Training centre is coordinating to nominate the officials to attend the trainings conducted by Indian Academy of Highway Engineers (IAHE) and Anna Administrative Staff College (AASC).

|

|

|

|

|

|

|

|

|

|

|

Training programme on Road safety – Relevant Highway Engoneering Aspect – Batch X (22.08.2022 to 26.08.2022)

|

|

|

|

III. ROAD SAFETY WING

An exclusive Road Safety wing is functioning with the aim of improving the road safety awareness and to minimize the road accidents and related fatalities with the following objectives,

- To analyze the road traffic accident data from i-RAD and other collateral sources.

- To coordinate with various stake holder departments and NGOs on issues of Road Safety.

- To offer suggestion in the junction improvement proposals and other road safety works as per standards.

- To carryout field/observational visits and suggesting suitable remedies including monitoring the post improvement.

At Coimbatore, some of the signals at crucial junctions were eliminated by providing roundabouts, thereby reducing the travelling time of road users. Road safety wing Engineers assist the traffic police in optimising the signal timings, resulting in traffic decongestion and saving time. Also, Engineers are creating road safety awareness by educating the school and college students on traffic signs and rules.

Under Comprehensive Road Infrastructure Development Program (CRIDP), 532 Number of Road safety works for an amount of Rs. 191.37 crore have been taken up during 2022 -23.

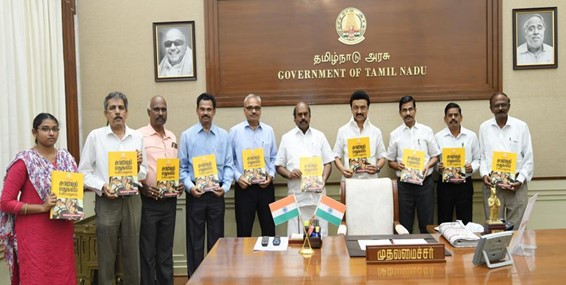

Hon’ble Chief Minister released the “Guide for Road Safety Awareness” on 22.08.2022 to create awareness about Road Safety. Also Hon’ble Chief Minister reviewed the status of the Road Safety aspects with all stakeholder departments on 03.01.2023.

|

|

Hon’ble Minister of Highways and Minor Ports has conducted Road Safety Awareness meetings so far in 11 districts viz Namakkal, Chengalpattu, Ooty, Theni, Madurai, Thoothukudi, Sivagangai, Ramanathapuram, Erode, Coimbatore and Virudhunagar with the participation of various departments, NGOs, Associations and public. Through these meetings, more awareness of Road Safety has been created among public and all road users so that accidents will be reduced.

Road Safety awareness meeting in Namakkal District on 10.11.2021

|

Road Safety awareness meeting in Chengalpattu District on 14.12.2021

|

Road Safety awareness meeting in Nilgris District on 21.12.2021

|

Road Safety awareness meeting in Theni District on 18.05.2022

|

Road Safety awareness meeting in Madurai District on 19.05.2022

|

Road Safety awareness meeting in Thoothukudi District on 20.05.2022

|

Road Safety awareness meeting in Sivagangai District on 13.07.2022

|

Road Safety awareness meeting in Ramanathapuram District on 14.07.2022

|

Road Safety awareness meeting in Coimbatore District on 30.11.2022

|

Road Safety awareness meeting in Virudhunagar District on 23.12.2022

|